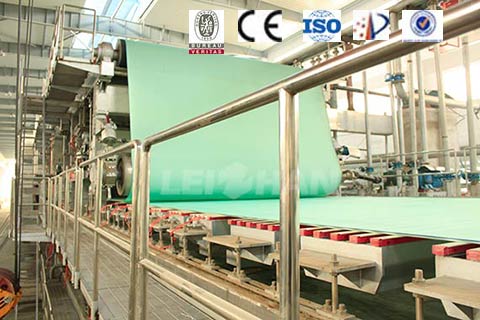

Double Layer Kraft Paper Machine

Double Layer Kraft Paper Machine is mainly used to make kraft board machine, corrugated base paper. This paper machine is mainly devided into headbox, fourdrinier section, press section, dryer section, sizing machine , calendering machine and reeling machine.

Headbox

Two sets of open headbox, which are respectively correspond to top layer wire and bottom layer wire. By controlling the liquid level in the headbox, the sizing head of the sizing agent can be controlled and stabilized.

Wire Section

Two layers, namely top layer and bottom layer. Main components: chest roller, forming plate, dehydration plate, vacuum box, couch roller, drive mesh roller, guide roller and rack, etc. Both the top layer wire and the bottom layer wire are matched with a forming wire.

Drying Part

Φ1500/Φ1800 dryer cylinder. Group transmission, with guide roller, dry mesh. Equipped with closed air hood.

Sizing Machine

The sizing machine is equipped with a chrome-faced metal roller, a metal roller wrapped with glue. The prelum way of the sizing machine is ripple pneumatic tyre prelum.

Calendering Part

Double roll calender. The upper and lower rollers are the metal roller, the way of pressure is tire pressure ripple.

Certainly, there is press section, if you want to know the details about it, you can email us.

Main Specification

| Paper Grade | Kraft paper |

| Certification | ISO, BV |

| Trimmed width(mm) | 1880-5800 |

| Basis weight(g/m2) | 80-220 |

| Operating speed(m/min) | 150-800 |

| Dimension(L*W*H) | up to each model |